Pyrolysers: Insights from the ground

Over the last two months, the LongStraw team has been on the ground setting up biochar production equipment across our projects in Kalahandi and Sambalpur.

India’s biochar sector is expanding at remarkable speed - but the technology ecosystem supporting it hasn’t fully kept pace.Indian fabricators still borrow from torrefied coal units, charcoal systems, and small coke ovens. But the resemblance is only superficial.

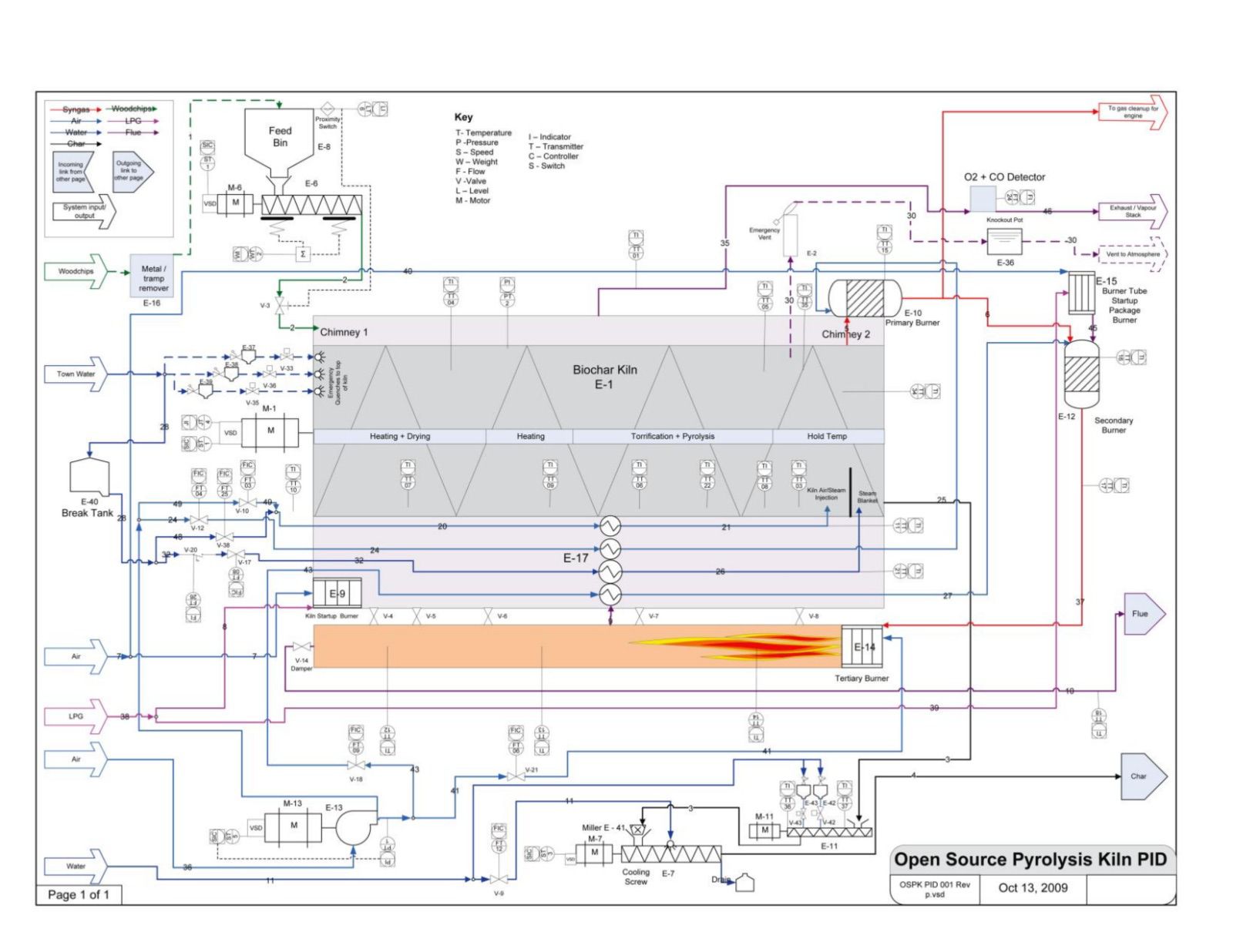

Producing biochar for carbon markets demands far more sophistication. The biggest divergence from traditional charcoal-making lies in syngas handling and the overall circularity of the process - both critical to minimizing embodied emissions.

This introduces several essential components:

Airtight, heat-resistant syngas recirculation systems

Multi-stage condensation units to extract tars, volatiles, and bio-oil

Reliable instrumentation and tight control loops

Emission control add-ons aligned with credit methodology expectations

1. Materials & Reactor Integrity

Biochar reactors operate under extreme heat, corrosive vapours, and tar-heavy gas streams. Material choice isn’t optional - it determines machine lifespan and char quality.

A credible reactor requires:

304/310S stainless steel in high-temperature zones

Corrosion-resistant surfaces or protective linings for acidic condensates

Proper refractory insulation for thermal stability and energy efficiency

Using mild steel or inadequate insulation leads to warping, leaks, loss of airtightness, poor char quality - and eventual machine failure.

2. Syngas Condensation & Gas Handling

Biochar systems rely on a closed-loop syngas circuit. Condensation is where most machines succeed or fail.

Effective systems include:

Multiple condensers for different temperature fractions

Negative-pressure management through ID fans

Accessible drainage and cleaning points

Designs that avoid tar blockages and maintain safe draft

3. Sensors, Instrumentation & Automated Control

Modern reactors need continuous measurement and smart automation:

Temperature sensors at multiple depths

Pressure/draft monitors with alarms for seal failures

PLC panels with AUTO/MANUAL modes

Data logging calibrated to MRV expectations

Every site is different. Every feedstock is different. And therefore every machine ultimately requires customization - in materials, insulation, syngas routing, condensation stages, and control logic.

The next leap for India’s biochar sector will not come from more machines, but from better-engineered, more reliable, more customizable machines built for climate markets rather than legacy charcoal applications.We move forward only when we abandon the idea that one-size-fits-all.

At LongStraw, this is the engineering foundation we’re building on the ground every day.